What is the purpose of this article?

The article explains how Rheonics density and viscosity sensors can be used for real-time remote data transmission in drilling rig sites. It focuses on how these sensors, which measure mud properties like viscosity and density, can be integrated into wireless communication systems such as LoRaWAN and WiFi to enable continuous monitoring, data visualization, and remote analysis in drilling operations.

What products are involved?

Rheonics SRD Inline Density Meter, Rheonics SRV Inline Viscometer, LoRaWAN gateways, WiFi gateways, Modbus RTU/TCP converters, Node-RED, MQTT brokers, Ignition SCADA, The Things Network (TTN).

TABLE OF CONTENTS

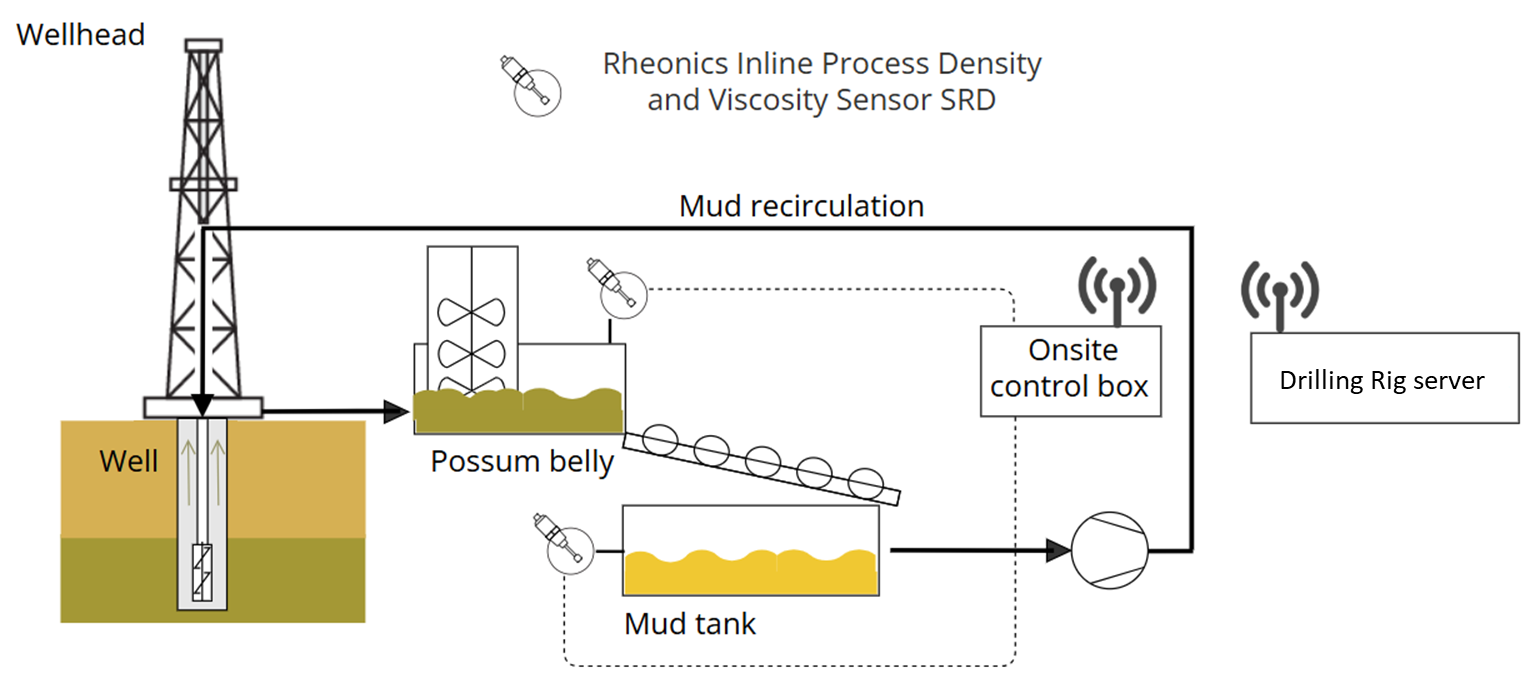

In remote rig sites, real-time data transmission is crucial for quick decision-making and operational efficiency. Rheonics sensors support a wide range of industrial communication protocols, providing a robust and standardized solution for seamless sensor integration and reliable data transmission to the drilling control system. This ensures accurate process monitoring and enhances drilling performance in demanding environments.A key component of drilling fluid management is surface logging, which involves real-time monitoring of fluid properties at the rig site to detect changes in well conditions. By integrating Rheonics density and viscosity sensors in key points of the rig site, like the suction tank and possum belly, operators can continuously analyze mud performance, identify early warning signs of well instability, and optimize fluid conditioning. Surface logging not only enhances well control but also improves drilling efficiency, reduces downtime, and prevents costly well failures, making it an essential practice in modern drilling operations.

1. How is remote data transmission done in rig sites?

Modern drilling operations depend on real-time data acquisition and automation platforms like Wonderware, Ignition, and other SCADA systems to monitor viscosity, density, and other critical parameters. To integrate these software solutions with LoRaWAN[1] or WiFi[2], a protocol conversion process is required to transmit Rheonics sensor data over a wireless network, ensuring seamless communication and reliable data access.

Figure 1. Remote data transmission to the driller cabin.

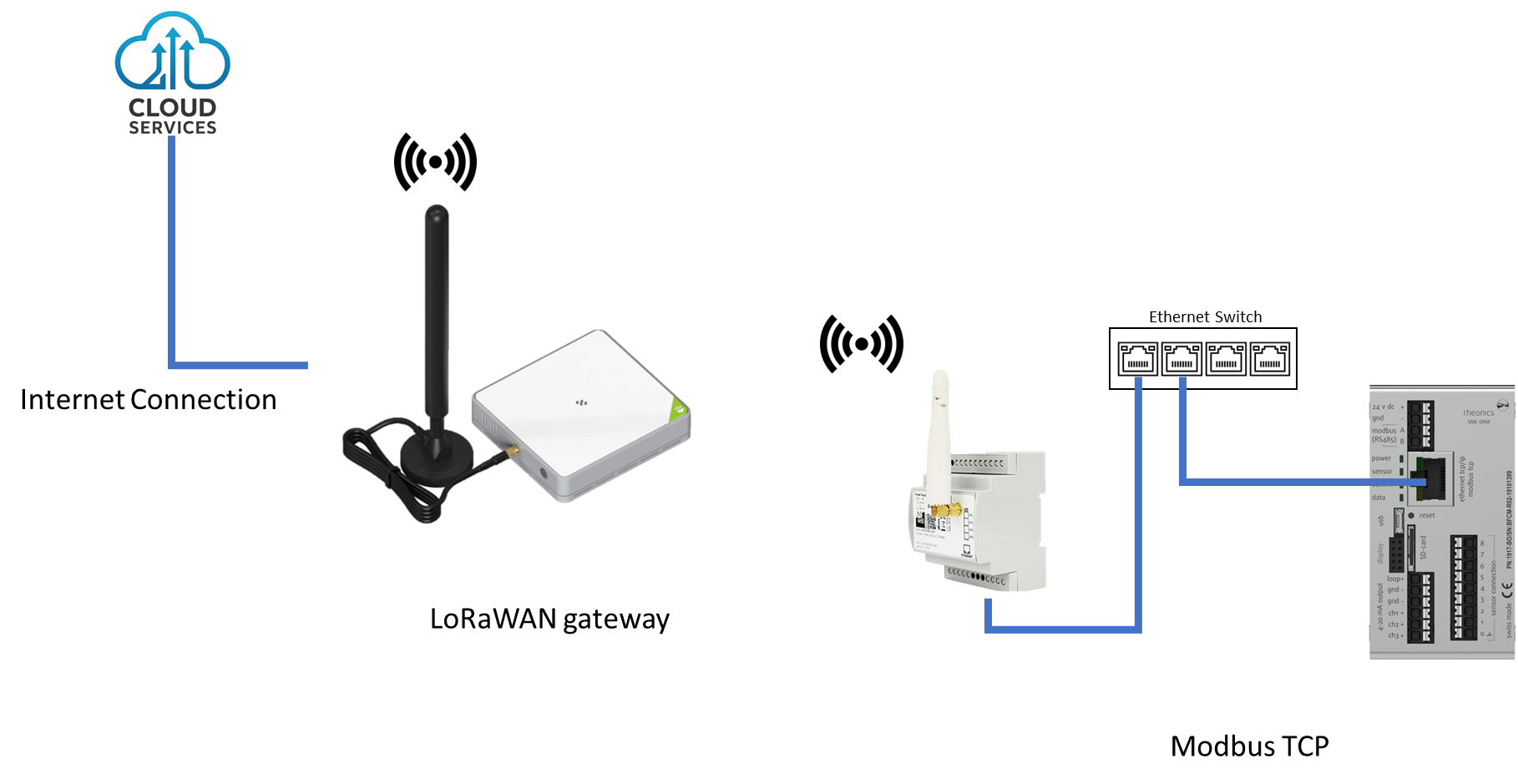

1.1. Converting Rheonics Modbus Protocol to LoraWAN or WIFI?

Rheonics sensors can use Modbus RTU (RS-485) or Modbus TCP for communication. To integrate them with LoRaWAN or WiFi, we need protocol converters or gateways that translate the Modbus data into a format compatible with wireless transmission.

Figure 2. Rheonics Lorawannetwork.

Figure 2. Rheonics Lorawannetwork.

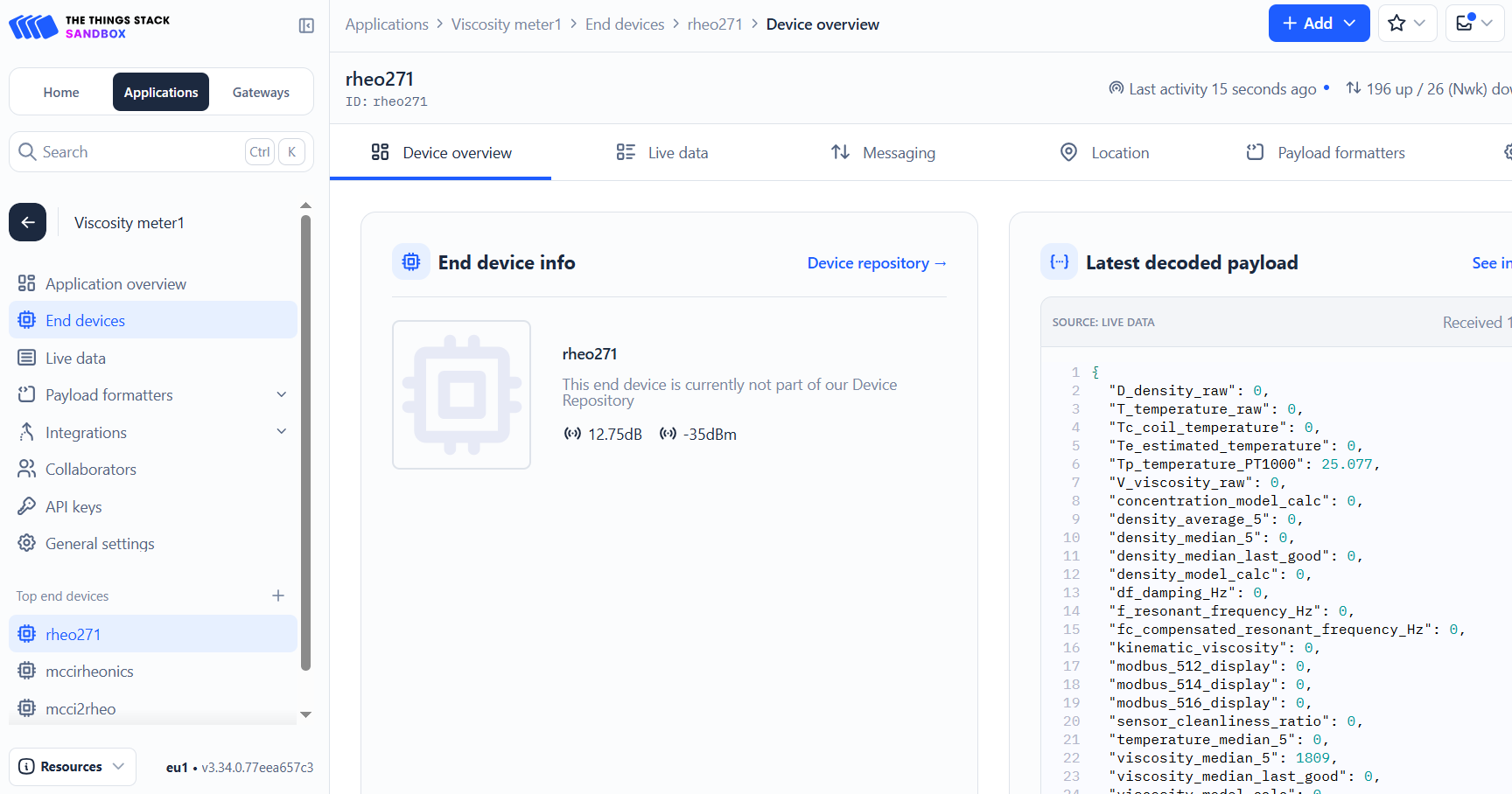

1.2. How do we observe data with LoraWAN or WIFI?

Rheonics viscosity and density sensors at the suction tank and possum belly continuously measure drilling fluid properties. The data is transmitted via Modbus to a LoRaWAN converter, which forwards it to a LoRaWAN gateway. This gateway can be registered with cloud services like TTN, ChirpStack, or Helium Network.

Figure 3. Data visualization in TTN from a sensor installed.

Figure 3. Data visualization in TTN from a sensor installed.

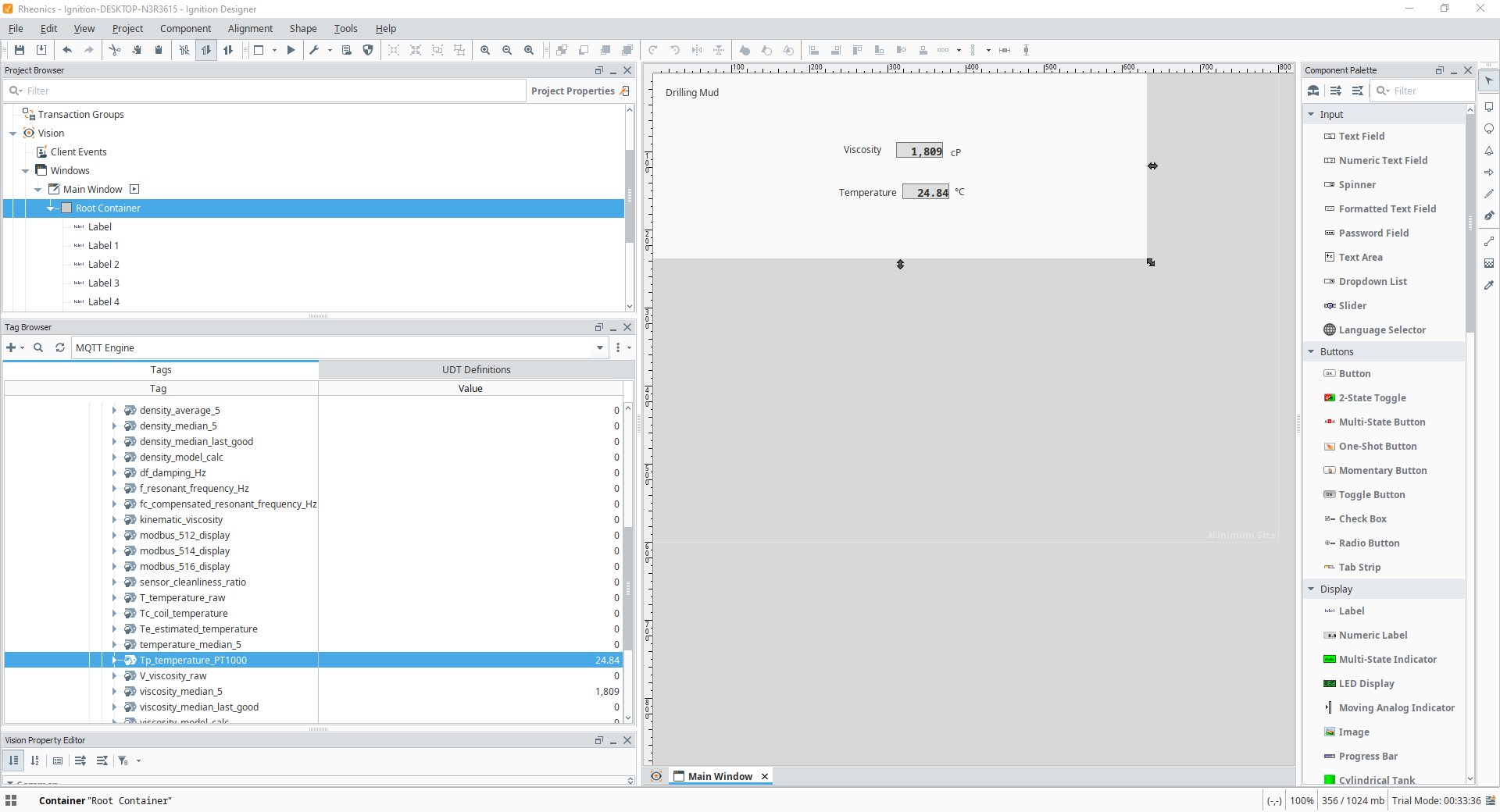

From there, the data can be sent to local systems like Ignition for analysis and visualization.

Figure 4. The ignition server is located in America.

Figure 4. The ignition server is located in America.

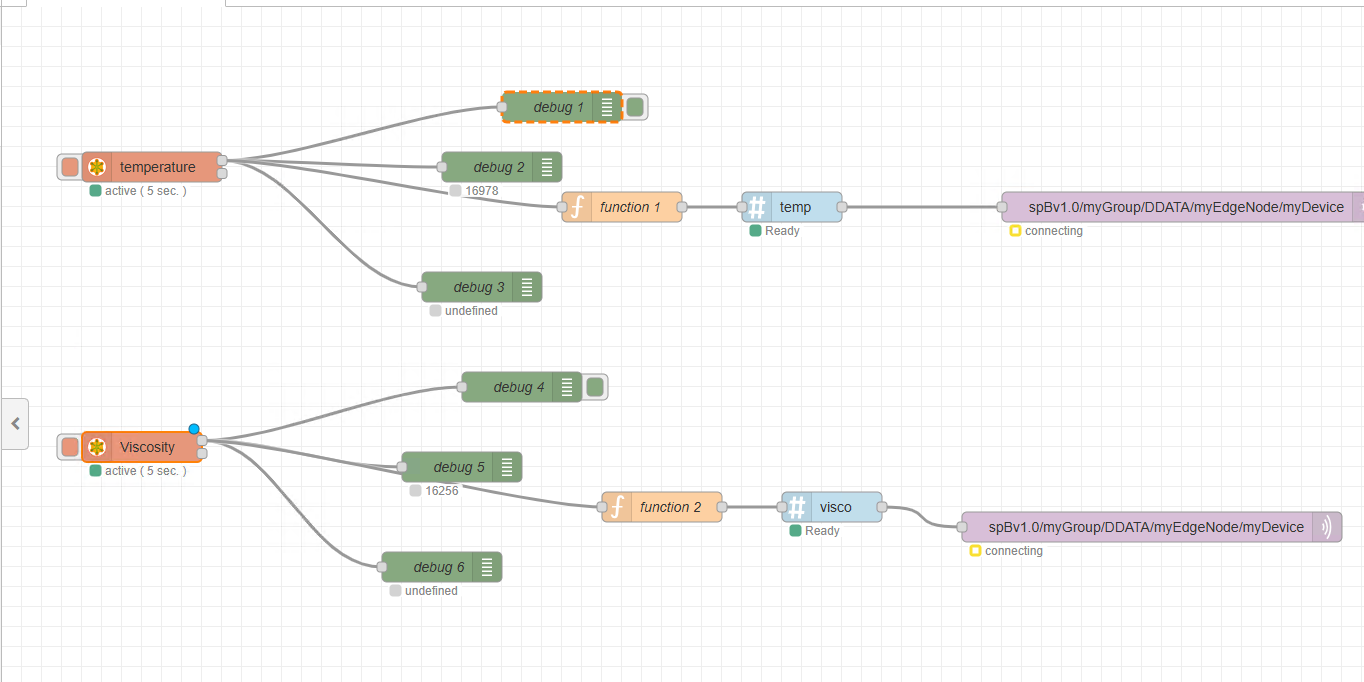

When implementing a Modbus-to-WiFi conversion setup, one effective approach is to use platforms like Node-RED to collect data from a Modbus-to-WiFi gateway and transmit it to a central MQTT broker for access in the driller's cabin.

Figure 5. Rheonics WIFI network.

Figure 5. Rheonics WIFI network.

Rheonics viscosity and density sensors typically communicate using Modbus RTU or TCP, and a WiFi gateway serves to convert this serial data into IP-based communication over a local wireless network. Industrial software such as Ignition can then access this data directly via Modbus TCP, MQTT, or REST APIs, while platforms like Wonderware can connect using OPC UA or native Modbus TCP drivers. This setup enables real-time wireless monitoring of sensor data on tablets, HMIs, or SCADA dashboards, providing engineers in the driller’s cabin with immediate visibility into critical process parameters.

Figure 6. Node-Red data received from a WIFI gateway installed in drill site.

Figure 6. Node-Red data received from a WIFI gateway installed in drill site.

Finally, the implementation of remote data transmission for viscosity and density monitoring at rig sites isn't merely a technological upgrade; it's a cornerstone of intelligent drilling. By seamlessly integrating Rheonics sensors and leveraging protocol conversion for wireless communication like LoRaWAN and WiFi, we unlock a continuous stream of crucial data from the heart of the operation – the suction tank and possum belly. We gain the ability to anticipate well conditions, fine-tune drilling fluids in real time, enhance overall efficiency, and significantly mitigate the risks associated with well instability and potential failures.

2. Resources:

https://www.thethingsnetwork.org/docs/lorawan/what-is-lorawan/

https://www.cisco.com/c/en/us/products/wireless/what-is-wifi.html